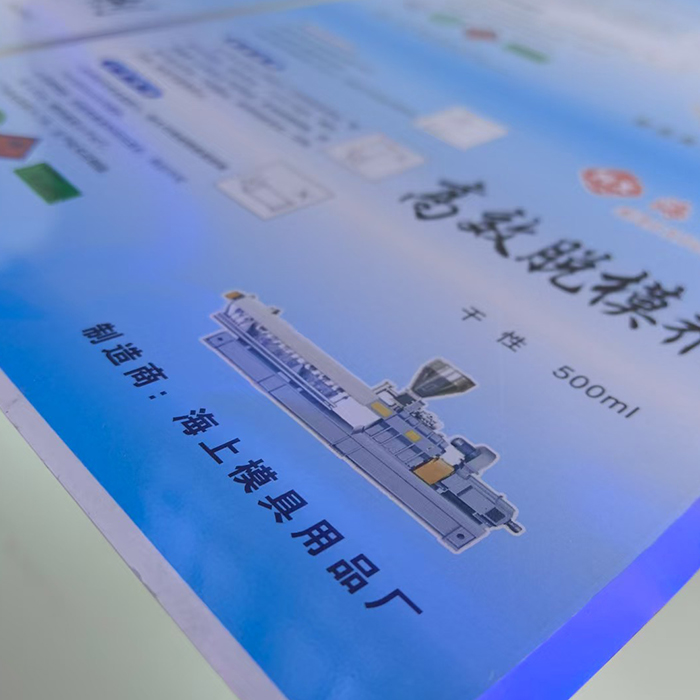

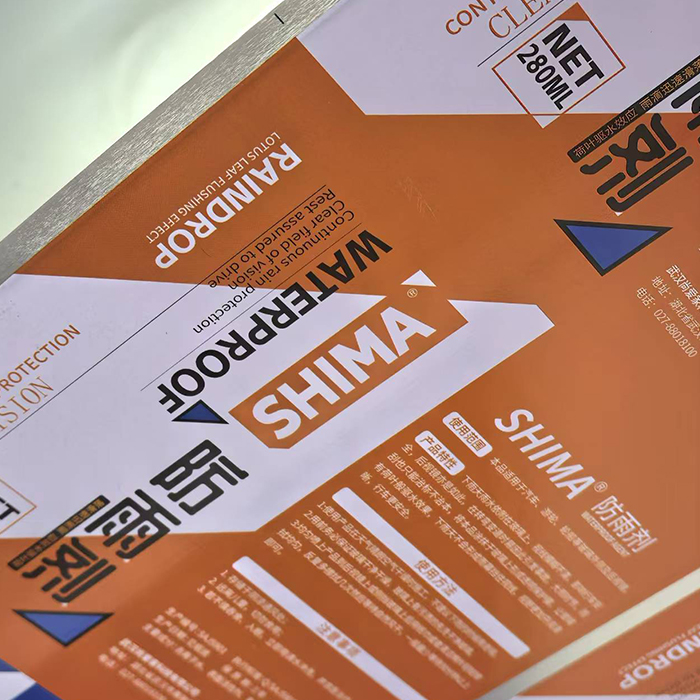

Steel plate for tinplate printing

Characteristics of tinplate printing

· Printing material: Tinplate (tin plated steel plate) has the characteristics of corrosion resistance, high strength, and easy molding, suitable for long-term storage of contents.

· Printing process: Special offset printing or UV printing techniques are required, as the surface of the tinplate is non absorbent and the ink needs to be cured by baking.

· Durability requirements: High temperature resistance (such as sterilization of food cans), wear resistance, and chemical corrosion resistance (such as acidic beverages) are required after printing.

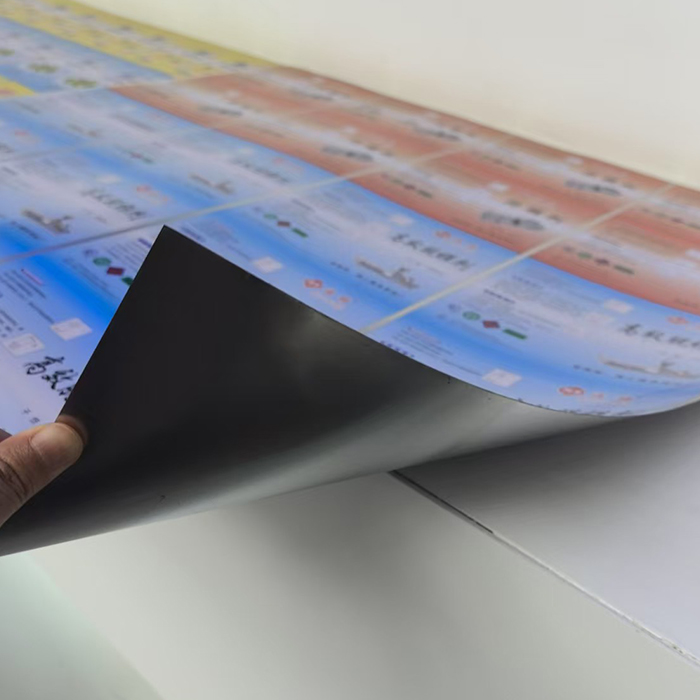

Printing process flow

Surface Treatment

· Clean the surface of the tinplate and remove oil stains.

· Apply primer to enhance ink adhesion.

· Mostly using four-color (CMYK) or spot color offset printing, some require multiple overprints.

· Use high temperature resistant and non-toxic ink (such as epoxy resin based ink).

Bake

· Cure the ink through a high-temperature drying oven (120-180 ℃).

Polish (cover with gloss oil)

· Apply protective varnish to enhance glossiness and wear resistance.

Forming processing

· After printing, the tinplate is made into cans, lids, etc. through processes such as stamping and curling.